What is Internal Ballistics?

Internal ballistics is the study of what happens to the bullet inside the rifle. Though the bullet spends only a brief time inside the rifle as it races down the bore, the factors that affect it here are of massive importance. The bullet does not operate like a rocket or an airplane upon leaving the barrel - there’s no new force being added to help it on its flight. It has to rely solely on the forces that push it through the barrel in the first place.

How Long is a Bullet in a Barrel?

Let’s take a look at how long it takes for the bullet to leave the barrel from the time you pull the trigger. As your trigger breaks, the sear pulls away. The hammer drops, the firing pin slams forward. After the firing pin strikes the primer, fire reaches up through the flash hole and sets off the powder. The time from the primer’s explosion to the powder’s ignition is somewhere around 0.002 seconds.

The bullet starts to move forward, propelled by the expanding wall of gas. Its highest velocity should happen just as it exits the barrel. For fast bullets (2700-3000 fps or more) exiting normal rifle length barrels (20-24”),

the bullet will accelerate for around 0.0007 seconds. During this time, it’ll accelerate at a rate of roughly 105 m/s2. In contrast, normal earth gravity pulls objects down at a rate of 10 m/s2.

In total,

once the primer is struck, a bullet will leave the barrel within 0.003 seconds or so. Adding on the time for the firing mechanism to move following the release of the sear, the bullet will exit the barrel around 0.005 seconds after the trigger breaks.

Considering that most barrels wear out after a couple thousand rounds, your barrel can sustain 5-10 seconds of accumulated bullet travel (or less!) over the course of its life.

The Stages of Firing

During this brief transit time, every component of your rifle and cartridge has an effect.

First, for a shot to go off, the primer must function. Primers either do or do not work. There is little to optimize in regards to the primer itself, except to ensure that the primer does indeed ignite.

The primer sends a 2000C jet of flame up into the propellant through the flash hole. Your case’s flash hole might have been formed unevenly by the manufacturer. It may be very narrow, delaying the initial reaction. It may be positioned out of center or angled toward the wall of the case, causing the burn to start on one side of the propellant and not in the center. To ensure a consistent ignition between rounds, reloaders might drill the flash hole to be a consistent diameter and angle.

Now that the powder is burning, pressure and temperature skyrocket. In this first moment, the bullet is still stuck in the neck of the case. The case immediately expands, sealing to the walls of the chamber as best it can. The closer your case matches the chamber, the less transformation that the case will undergo. In the worst situations, pressure will cause the case to rupture. When choosing cartridges for your rifle, please ensure a good fit. To give the case a chance to expand and fit the chamber, stick to brass cases. Steel cases are useful only in rare situations. If you’re reloading, you can reshape a brass case to exactly fit the chamber from the very beginning. This is known as sizing your case. However you go about acquiring your cases, try to aim for a tight fit to the chamber.

Fractions of a second later, the bullet leaves the case and contacts the rifling. The immense amounts of heat and pressure soften the case and the bullet, aiding the bullet in its escape from the neck. Most of the heat generated by this reaction can be found back near the chamber. In a perfect world, you’ll have enough time between shots for this heat to dissipate. If the chamber is still hot, the metal of the chamber (and barrel) will likewise soften marginally. It will also expand, causing your cartridge to fit a bit loosely. Even if your cartridge is properly sized for a cold bore, where the rifle is nice and cool, it may lose a bit of pressure when expanding to fit a hot chamber. To maintain high precision, give your rifle as much time as you can to cool down. If possible, also eject the spent case immediately after firing. The case will hold onto a lot of heat, and ejecting the case also ejects the residual heat it’s carrying.

When the bullet meets the rifling, it is torqued sideways. The lands of the rifling squeeze down on the bullet. The outer diameter of the bullet rubs against the depths of the grooves. Your bullet’s diameter should very closely match the diameter of the grooves (the caliber). If the bullet is too wide, the grooves will also deform the bullet. The bullet will face higher than expected friction, increasing the heat in the barrel and losing speed for the bullet. Of course, if the bullet is far too wide it’ll simply jam in the barrel. Meanwhile, a bullet that is too narrow will leave room for pressure to escape around it. This also loses speed for the bullet. To ensure a full and proper use of the propellant’s pressure, the bullet must fit the bore as perfectly as possible or be just a tiny bit wider.

The propellant (powder) is not burned up all at once. It follows the bullet through the barrel, expanding in the high pressure wave of gas. The heat and pressure are high enough that powder will continue to ignite down the length of the barrel. As the bullet races towards the end of the barrel, this reaction will slow. The powder will add less and less pressure to the system, until it is finally all burned up. There are many formulations of powder. Some burn very quickly at the start and very little at the end, while others burn evenly throughout the entirety of the reaction. If you’re reloading, it becomes very easy to change the type and amount of powder in your cartridge. Certain powders work very well with particular combinations of bullet and barrel, maximizing precision. If you’re shooting factory rounds, you’ll be forced to test different cartridges to see which cartridge offers the most precision for your particular setup.

As the bullet travels down the bore, it will be spun around by the rifling. If the rifling is uneven, the bullet will be compressed and spun in unusual ways. This will cause it to later fly unevenly. Ideally, the rifling should be of consistent dimensions down the whole length of the barrel. For the highest precision, the lands and grooves should have smooth surfaces - a mirror finish is the absolute best. If the surfaces inside your bore are rough and pitted, this will increase the friction on the bullet, also increasing the heat while simultaneously reducing velocity.

The rifling should also be the correct twist rate for the particular bullet you’ll be firing. Twist rates that are too fast will cause the bullet to emphasize any irregularities in flight - irregularities such as those caused by uneven rifling. A twist rate that is too slow will not stabilize the bullet in flight, potentially allowing it to tumble and wobble after some distance. To ensure that your bullet flies in a nice, tight spiral, make sure the rate of twist is proper for the weight of the bullet.

What are Barrel Harmonics?

The final consideration for internal ballistics lies in the barrel’s

harmonics. When you fire a round, the massive explosive force causes your barrel to vibrate. This vibration causes the muzzle to whip around. These movements are not as extreme as a whipping fire hose, but they are enough to notice an effect on your precision.

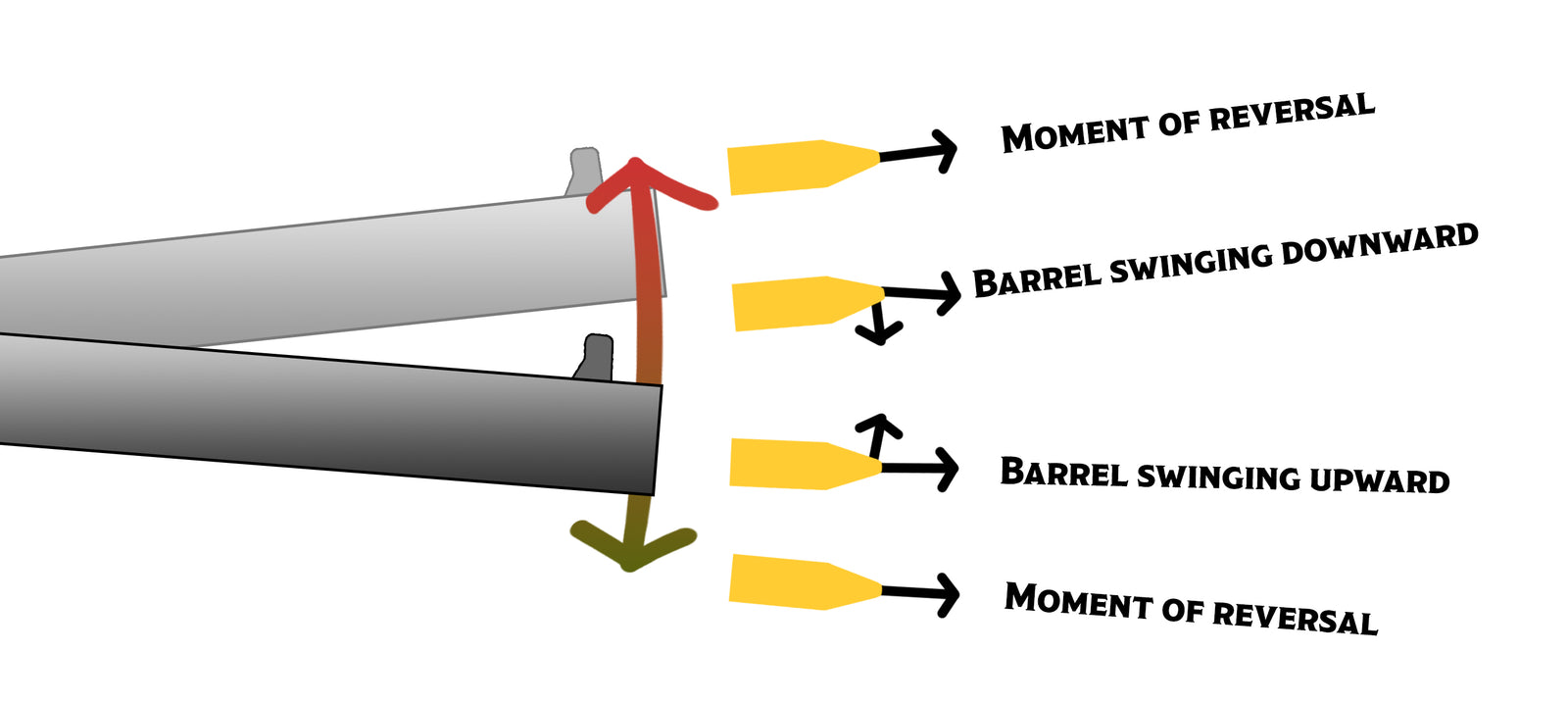

Though the bullet may be traveling at thousands of feet per second, the vibrations will be traveling tens of thousands of feet per second. Your bullet will not exit a perfectly still muzzle. Instead, the muzzle will be moving in some oscillating direction. As it moves, it will swing far out to the side, then back through the central ‘at rest’ position, then off to the other side. If the bullet exits the muzzle while being swung to one side, it will leave the barrel at a small angle with a tiny bit of sideways momentum.

When the muzzle reaches the extreme side of a whipping motion, there is a brief moment where the muzzle halts before reversing direction. If the bullet leaves the barrel at this precise moment, it will have none of the extra sideways force applied to it. Strangely, this does mean that the bullet will leave the barrel when the muzzle is pointed slightly out of center. You’ll just have to adjust your aim from this point onward, taking into account the slight offset from the barrel’s at rest position.

Much like a musical instrument, your barrel can be tuned. The most important factor in accurate shooting lies in the repeatability (and predictability) of your setup. If you can tune your barrel and load such that the bullet always exits at the same resting moment of the vibration, it will have a much more predictable arc of travel. As an example, a barrel with poor harmonics might spread its shots out across 3 inches at 100 yards, even if you aim and fire perfectly. Upon tuning such a barrel, it’s not uncommon for the spread to reduce to 1 inch. This will be the work of a capable gunsmith or avid reloader, but is highly encouraged for long range shooting.

My favorite theory is that the barrel should be tuned such that the faster bullets exit at the bottom-most trough, when the end of the barrel points down. This way, slower bullets will exit a fraction of a second later, when the barrel is beginning its upward swing. This added upward heft at the start of the bullet's flight may compensate for the slow bullet's originally lower impact.

Other ideas include nullifying the vibration as much as possible - harmonically deadening the barrel. But that's a long discussion for another time.

As the barrel vibrates from the round going off, an exiting bullet might pick up a bit of sideways momentum depending on when it leaves the barrel.

Leave a comment (all fields required)