The case is the part of the cartridge that holds all the other components together. Before we talk about all the things that will be stuffed into it, it’s a good idea to know where the stuffing happens! The case is also known as the brass. You might hear someone at a range tell you, “pick up your brass,” or, “save your brass.” They’d be referring to the empty, left-over case after the round has been fired. Sometimes the case is also known as the shell, though this term is also used for shotgun cartridges.

A box of empty cases.

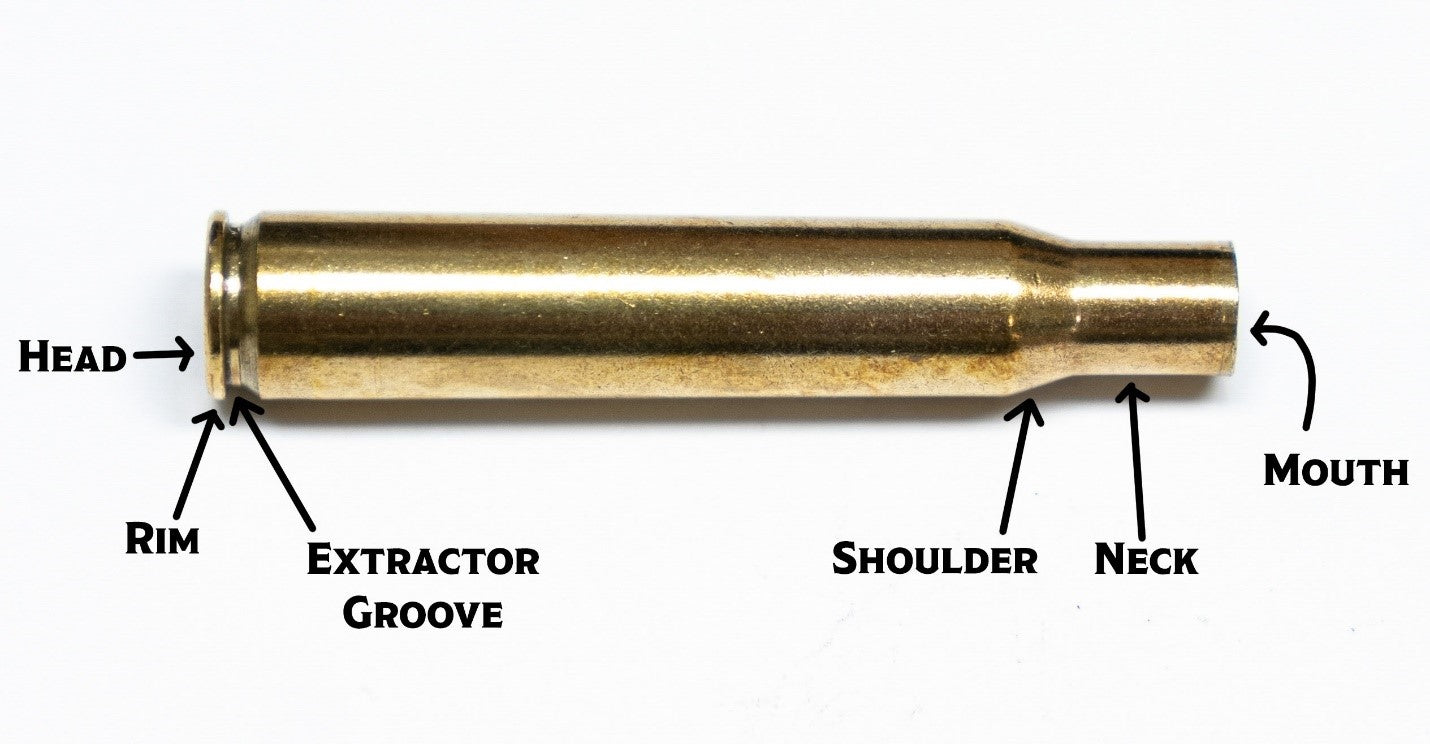

Imagine the case as a sort of bottle. This bottle contains powder , and the cork in the neck is the bullet. The bullet is stuffed a fair way into the opening of the neck - the mouth. The shape of a case is remarkably similar to a simple bottle - in modern high-power rifle rounds, it’ll have a thick bottom and narrow neck. This narrowing of the case is known as a bottleneck. The angled edge formed by the bottleneck is known as the shoulder. For a bottlenecked case, the shoulder is the surface that decides how far a cartridge will fit into a chamber. At the bottom of the case, you’ll find the head. The head contains the primer pocket, which holds the primer if the cartridge uses an external primer. The head is also the location for the rim and extractor groove. The rim and extractor groove are the places on a case where a rifle will grab to feed and extract the cartridge.

The distance from the head to the shoulder is known as the headspace. If your cartridge has too much headspace for your rifle, it simply will not fit. If it has too little, it will leave a pocket where pressure can escape in dangerous ways.

Your case will have a bottleneck if using a bullet of narrower diameter than the head. Some cases, especially of pre-1900 design, will be straight-walled instead. A straight-walled case has no bottleneck, and the bullet is as wide as the rest of the case. Straight-walled and bottlenecked cases are markedly different in terms of pressure and bullet size.

A normal-looking bottlenecked case. The bullet, powder, and primer have been removed - but the primer pocket is currently hidden from view.

Regardless of whether the case is bottlenecked, the neck often starts life slightly narrower than the bullet by about two thousandths of an inch. This slight narrowing exists to keep the bullet held firmly in place. The amount of grip that a case neck has on a bullet is known as the neck tension. There should be enough neck tension that the bullet will not be pushed into the case by normal handling. In contrast, having too much neck tension may result in a dangerous amount of pressure in the chamber as the round goes off. The bullet has to fight against the neck tension to escape the case at the very start of its journey, and too much neck tension can be an impediment as the pressure behind the bullet builds.

To double check whether your cartridge has enough neck tension, grab a round and push down on the bullet with a finger with a moderate amount of pressure. If the bullet slides into the case, it’s no good. Rounds with too little neck tension may end up having the bullet push itself into the case as it’s being fed into the rifle’s chamber to be fired. When the bullet scoots backward, it compresses the powder behind it in potentially dangerous ways. It may also be pushed back far enough that it will slip out of alignment and enter the barrel at an angle upon firing. Neither of those situations are any good, so a round that has insufficient neck tension should not be fired. Instead, hand it to someone with reloading equipment to tidy up for you - all the pieces can be re-used quite readily.

To ensure proper neck tension, some rounds may be crimped. After the bullet is placed in the mouth of the case, a special tool is used to squish the brass around the bullet.

On the left, a bullet that has been pushed back into the case. On the right, a bullet sitting at its normal position.

Precision shooters that load their own rounds will typically trim the neck to be a consistent size across their loads, specifically at the length and diameter their rifle likes best. Factory ammo may have a slightly variable neck length, though for our purposes this variability will often work just fine. Remember - every minor detail can be a help or hindrance as you shoot at farther distances.

If the neck is too long, it may cram into the rifling in your barrel, crimping the neck around the bullet and increasing pressure. If the neck is too loose, the bullet may be pushed back into the case purely by accident. In factory ammo, these events are both very unlikely. When it comes to handloading, I’ll leave it to you to decide what’s proper.

If your case is far too long, you’ll notice almost immediately at the range when the round is very difficult to force into the chamber. To double check whether your cartridge is just a bit too long, try loading one in the rifle. Work the bolt, closing the round completely in the chamber as if you were going to fire. Leave the safety on. Rather than firing, open up the bolt and extract the round. Look around the perimeter of the bullet and the rim of the neck. If you can see scratches or dents from the rifling, then the case or overall cartridge is too long. In many cases, the round will still fire properly - but not as efficiently as a round of the right size.

Please note that some rifles (discussed in Chapter 3.3) will sometimes scratch a bullet or case as part of feeding the round. It might be a little difficult to tell at first what the root cause of a problem is - don’t hesitate to ask other rifle owners!

An example of the mark lands can leave, though this time shown on much softer lead. Similar dents can appear in your brass if the neck is far too long.

Cases are typically made of brass, but are also occasionally steel. Brass cases are considered all-around better in nearly every respect, but for reasons you may not expect. When the round is fired, the hot expanding gasses form-fit the case to the chamber of your rifle, sealing it against escaping gas. Brass is more malleable than steel, so it creates a better seal. Steel cases aren’t as malleable and don’t form as perfect of a seal, so escaping gas and unburnt powder can feed back into your rifle in the form of fouling (a sort of dirty buildup). Lost gas also means lost pressure, which translates to lower velocity and force for your bullet.

Steel, on the other hand, is stronger. If your rifle is the sort that extracts the round with a very great deal of force, a brass case may end up simply tearing. Steel cases are preferred in these rare situations, as they don’t tear. This happens occasionally in older AK’s (a Russian line of rifles), but not as often in the sort of rifles that are chosen for precision long-range shooting.

I’ve fired plenty of rounds that simply would not extract. After pulling the trigger, I would try to work the bolt to remove the empty case. I could turn the handle up, but no amount of effort would get the bolt to move back and pull the spent case from the chamber. Eventually I would have to hammer back the bolt of the rifle with a literal hammer until it pulled the case free. Even in such rough circumstances, the brass cases did not tear. It’s very rare for a rifle to absolutely require steel ammo. Unless you’re firing particular old Russian rifles, it is unlikely you will need steel as a matter of course.

Two versions of the .223 Remington - the upper with a brass case, the lower with steel.

Fortunately, case sizes for commercial rifles are standardized. There will always be some minor variations between cases - machining is very good nowadays, but never perfect. Firing factory standard ammunition out of a factory standard barrel, you may find some cartridges simply work better with your rifle in terms of precision or feeding. Figuring out which ones work best for your setup, or how you have to change your setup to be more effective, is only half the journey.

The chamber of your rifle will be built to fit one standardized case style. Though the bullets they hold may arrive in many lengths, weights, and shapes, the case itself should be a standard size and shape.

Standing at the left is a .308 Winchester cartridge with a hefty 175 grain bullet. Arranged at the side are other .308” caliber bullets, though with quite different weights.

Cases will often also be described by the total volume of water they can fit. This helps to verify that a particular cartridge is the same size as another one, and gives handloaders an idea of how much room there might be for powder behind the bullet. Some cartridges have more than one name, so it’s good to have a way to double check. The amount of water in this instance is measured in the unusual unit gn, or grains. A common .308 Winchester case has a volume of 56gn of water. A .30-06 case, from the historic M1903 Springfield rifle, sits at 69gn. A .45-70 case is a little bigger, at 79gn. The powerful .416 Rigby fits a whopping 130gn! A grain is equal to .0648 grams, which is about .0648 ml of water. This translates to a .308 Winchester having a volume of 3.62 ml and a .416 Rigby having 8.42 ml.

Leave a comment (all fields required)