1903.

Say that string of numbers in the firearm community, and someone’s going to know what you’re talking about.

So… what are we talking about?

A Quick History

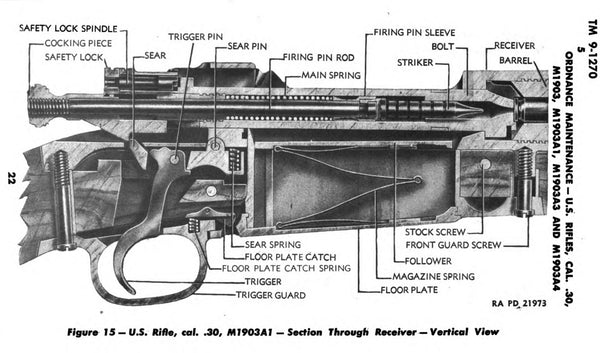

The 1903 is a rifle. Chambered in .30-06 (‘thirty ought six’), it’s made of wood, metal, and a firm butt plate and weighs a bit over 8 ½ lbs. It’s a bolt action rifle that has been around since (you guessed it) 1903. Originally named the “United States Rifle, Caliber .30-06, Model 1903”, it’s now colloquially (and officially) named the “Springfield M1903.”

Way back in 1898, the United States stepped into a conflict with Spain via the Cuban War of Independence. At the time, the Spanish troops were using the M1893 Mauser to great effect. The U.S. troops’ Springfield Model 1892–99 Krag–Jørgensen bolt-action rifles were not as effective. In the Battle of San Juan Hill, 750 Spanish regulars delayed the advance of 15,000 U.S. troops. On the same day, not too far away, 540 Spanish regulars held off a combined force of about 8,500 troops for 10 hours.

As a result, a U.S. Army Board of Investigation was commissioned. They recommended replacing the Krag. It had been in service in the U.S. Military for only 9 years when it was finally replaced; 1894-1903.

The Krag couldn’t handle higher-pressure rounds. To top that off, the magazine was slow to load. In 1899 (just after the Spanish-American war), The U.S. Army tried out a higher-pressure round in the Krag, but the locking lug on the bolt couldn’t handle it. They designed a stripper-clip modification for the Krag as well, though it was a stopgap measure to keep up.

In the long development to the Springfield 1903, the military licensed and studied many Mauser components. Mauser’s patented 7.92x57 bullets were later modified into the 30-06 Springfield ammo (7.92 mm = 0.31 in; 7.62 mm = 0.30 in). The Mauser G98 bolt action rifle - known as the

Gewehr 98 - also provided a useful foundation.

When the 1903 was finally adopted, it replaced more than the Army’s Krag; It also stepped in place of the Navy’s and Marine’s

Lee Model 1895 and

M1885 Remington-Lee. The

Springfield Model 1873 was likewise swapped out.

Development of the 1903

At the end of the Conflict, the Spanish troops in Cuba were made to surrender their Mauser Model 93s. Thousands of rifles were turned over to U.S. troops. Springfield Armory spent some time studying them, and decided that the Model 93 design was overall superior to the Krag.

At first, the newest prototype was a mix between the 1898 Krag and the 1893 Mauser. It ended up being similar to the final

Mauser M92 prototype (“Rifle No. 5”) in the U.S. Army’s rifle trials of 1892. This new rifle design was known as the “U.S. Rifle Model 1900 .30 prototype”.

The following year saw the next prototype - the “U.S. Rifle Model 1901 .30 prototype.” This again combined portions of the Krag and the 1893 Mauser, alongside the Gewehr 98. From the Krag came the cock-on-opening bolt, the 30” barrel, the stock, and the sights. From the 1893 Mauser: the locking lugs, external claw extractor, and staggered-column magazine. And from the Gewehr 98, a large safety lug was attached to the side of the bolt behind the extractor, engaging the receiver bridge to prevent the bolt from moving backwards when fired. To top it all off, the bolt handle was bent downward a bit to make operation easier.

Springfield was so confident in the Model 1901 design that they nearly began producing whole rifles, and did actually begin manufacturing some of the parts. Unfortunately, a few more changes were needed.

It had been discovered that barrels could be shortened to 24”. The longer 30” barrel offered no real ballistic advantage, but did add weight and bulkiness. By shortening the barrel to 24”, the military also did not have to produce both a carbine and full-length rifle version - the carbine originally being for mounted troops or cavalry.

Another small change was the addition of a bayonet storage toward the fore end of the stock. The bayonet itself would later be a point of contention.

This, in all, became the

M1903. Its first official year of production was 1903, and it was officially adopted by the Army in the same year. The Marines would adopt it later, in 1909.

After 1903

The U.S. government was quickly on the hook to Mauser, to the tune of $250,000 (about $7.5 million today). Mauser Werke had brought and won a lawsuit against the U.S. government for the M1903’s use of Mauser designs. This did nothing to stop production, though settlement on the case was delayed for years.

Regardless, the federally-owned Springfield Armory pumped out 80,000 of these rifles by the start of 1905. Perhaps a little too quickly, as more changes were on the way. President Theodore Roosevelt took issue with the ramrod-type bayonet then being mounted on the M1903. A new type of blade bayonet was designed (the M1905). While the M1903s were being retooled to accept the M1905 bayonet, the armory also took the time to upgrade the rifles to the type 1904 sights.

However, in yet another twist, experiments revealed that a slight change to the ammunition could improve its performance drastically. The rifles were switched from the .30-03, 220 gr (2,300 fps) case and bullet to a slightly shorter-necked 150 gr, firing at 2,800 fps. Perhaps the biggest difference, aside from weight, was the change from round-tipped to pointed Spitzer bullets. This new cartridge, adopted in 1906, became known as the “Cartridge, Ball, Caliber .30, Model of 1906”, M1906 ammo - better known as .30-06 Springfield. The sights were changed again to accommodate the new ballistics.

Around 1905, the process of star gauging the barrels was starting to be employed by the military. This process tested the sizing tolerances of the barrel by drawing a sizing device through the bore in 1-inch increments. If the barrel passed this test, it was stamped with a small star motif on the crown of the muzzle. While this gauging method was often employed to determine if rifles met sharpshooter precision standards, it was not limited to that purpose.

By the time of the Pancho Villa Expedition (1916), the 1903 Springfield was standard issue for US Forces. Leading up to this exploratory expedition in U.S. military force, a few different alterations were making their way onto service weapons. One occasional upgrade was the fitting of a Warner & Swasey Model M1908 or M1913 Musket Sight. What we would now know as Telescopic Sights.

The Warner & Swasey model M1908 was designed by Ambrose Swasey, co-founder of the optical firm. It had a fixed 6X prismatic arrangement, keeping the eyepiece low and the objective above the mirage of a heated barrel. It also weighed 2 ¼ lbs, being made mostly out of painted brass and bronze. The top of the scope held a brass plate stamped with adjustment and ballistic information. The scope itself mounted onto a dovetail block, offset to the left from the line of bore. This both allowed ammo to be easily loaded without removing the scope, allowed the scope to be easily removed when needed, and enabled the rifle to maintain use of its iron sights. It came with a simple crosshair reticle and three stadia lines for bullet drop compensation.

However well-intended, the M1908 scope had a few design and construction issues. The lenses were easily knocked out of alignment (and the ‘03 has a pretty good amount of kick!). The 2+ pounds of scope hanging to the side of the rifle made the entire setup unbalanced. The eye relief was a little over an inch - so shooters had to use a protective eyepiece cushion if they wanted to avoid scope bite. The rubber eyepiece would suction onto the soldier’s eye during recoil, which would not have been helpful in a firefight. Over time, the internal black coating would flake off and cover the internal lenses, which often had additional clarity issues from moisture leakage.

To address these issues, the M1913 scope was entered into the field. The mounting style (offset dovetail block on the side of the rifle) stayed the same, as did the prism-using shape of the scope. Now, however, the eyepiece’s protective cup came with holes pre-drilled to prevent the eyeball suction problem. On top of that, the scope’s power was reduced to 5.2x to improve image brightness.

All other issues from the M1908 scope largely continued - water leakage, coating flaking, lens instability, black eyes. The US Army had bought 2075 of the M1908 optics, between 1909 and 1912. Conversely, the M1913 scope saw 5,730 sales to the military - though 4,200 of the scopes weren’t mounted or even issued. Though rare, you can still find unused M1913 W&S sights in their original leather cases. The W&S optics were largely sold off or removed from U.S. rifles by the 1920s.

The Marines would acquire M1903 rifles beginning in 1909. Originally, they had also requested a handful of the W&S scopes be sent along as well, to aid in marksmanship training. They decided not to utilize those scopes for very long, and soon switched to testing the new Winchester A5 scope - Style A, 5 power. The A5 scope was simpler in design than either of the Warner & Swasey scopes; it was a straight-tube scope with externally adjusting mounts. The scope’s rings would mount on to blocks that were attached to the rifle, simplifying replaceability and repair. To avoid drilling the receiver, the Marines experimented with placement of the blocks in other locations. The forward block went forward of the receiver (to avoid potentially damaging the core of the rifle), though the rear did not settle down for a while. In addition, the blocks’ original straight design did not not allow the scope rings to clamp tightly, causing the scope to eventually slide off the blocks. There was no self-tightening taper or crossbolt recess in use (yet).

Initially, the blocks for the A5 scope were mounted around 6 inches apart, which made the adjustment values 6/10ths of an inch at 100 yards. The Marines continued to experiment with scope placement for their rifle competition team, eventually settling on a spacing of 7 and 2/10ths of an inch - perfect spacing for half-inch adjustments at 100 yards. Eventually, a private-sector ballistics team would develop the Mann-Niedner tapered blocks to alleviate the slippage issue. The blocks employed a slight taper to allow the scope rings to tighten to the blocks with every shot. While useful for keeping the scope on the rifle, it meant the rings had to be delicately hammered off of the blocks in order to remove them.

Existing scope blocks or rings were modified and replaced to switch to the new Mann system. Later on in spring of 1917, Niedner would be contracted to drill 1,650 rifles for the marines for use in WWI. Due to potentially anti-American remarks made publicly, the Marines did not complete the contract with him and sought mounting equipment elsewhere. Winchester’s response - the Winchester #2 blocks (later renamed Springfield Marine) - were the basis for future externally-adjusting scope mounting blocks. They followed the Mann designs with a few differences in taper and thickness.

Around the time that the M1908 and M1913 scopes were being fitted and tested, another upgrade was on the way - the Maxim Silencer. By 1907, Sir Hiram Maxim had begun trying to apply his soon-to-be-patented ‘Silent Firearm’ device to the M1903. By 1908, he had designs for a shortened barrel M1903 with a silencer attached to the muzzle-end. (And, not long after the war, he also had designs for the muffler now attached to your car’s exhaust).

In 1909, the Chief of Ordnance recommended against silencers, as the slow escape of hot gas would be a beacon of smoke on a cold day. On top of that, it was difficult to affix a bayonet. By 1910, a new version of the silencer had been designed to address these various issues. By all accounts, it worked quite well - reducing felt recoil (and sound) by one third, functioning for hundreds of rounds sequentially, and not reducing accuracy.

An added bonus - the Maxim silencer hid the flash from the muzzle. A quality noted at the time for its potential in night operations. Throughout the continued development of the model 12 and model 15, Maxim would insist on the silencer’s use not only for guard harassment and sniping, but also for helping city-born recruits become accustomed to the sharp recoil and noise of the M1903. The military later decided to turn to .22 caliber training rifles to resolve the latter point at less expense. The Maxim silencer Model 15 was 1 inch in diameter and extended 7 inches past the muzzle. It had a bore of .375” to allow the .30 caliber bullet to exit cleanly.

Some effort was made to pair the M1908 or M1913 W&S sights with the Maxim Silencers on the 1903 platform, prior to General John Pershing’s Mexican expedition against Pancho Villa. Among Pershing’s command were Lingler’s Sharpshooters, equipped with W&S 1913 sights and the occasional Maxim silencer, intended to be a field test and capability demonstration of the new sharpshooter standard.

Around 1915, discussions had been taking place in the military to outfit two rifles per company with silencers and the W&S musket sights. Through the early 1910s, however, it seemed that the military focused more on small-scale acquisitions of silencers (both Maxim’s and Moore’s versions) and only a couple large purchases of sights - many of which were not mounted. Often these purchases were made to either test the equipment until destruction, or were intended for use in a particular conflict and were made too late for deployment.

WWI

By the time the U.S. entered WWI, over 800,000 of the 1903 rifles had been produced by Springfield Armory and Rock Island Arsenal. Pre-war production had been plagued with a combination of questionable metallurgy and occasional improper ammo use. The main issue was in excessive temperatures in the forging process, which burnt out the carbon and left receivers brittle.

Pyrometers were installed in the forging furnaces in December of 1917 to alleviate the forging issue. This change occurred at serial number 800,000 for Springfield Armory and number 285,507 at Rock Island Arsenal. Rifles with serial numbers under these are known as low number M1903 rifles. Rifles made after this point are sometimes termed “double heat-treated.”

While much of history remarks on Germany’s effective use of snipers, it’s worthwhile to mention the American, British, and Canadian forces as well. Earlier in the war, Canadian forces had ordered a small quantity of Warner & Swasey M1913 sights, though handled the finishing of the mounting blocks in their own way. Across the pond, British troops made use of Maxim silencers so effectively as to be named “Whispering Death.” American sharpshooters were trained in small numbers by experienced British and Canadian sharpshooters at newly developed Schools of Sniping. Most of the sharpshooter rifles for American troops were manufactured in 1916 and 1917, and only saw wider use at the very end of the war.

As an interesting side note, Captain Herbert W. McBride describes effective mounting of the M1913 scope while serving as a sniper with the Canadian Army. His method was to wedge a piece of safety razor into the mount and rust it in place with saltwater. Allegedly, it would fasten on so well that the armorer found it nearly impossible to remove.

During the war, Maxim’s silencers had a competitor by the name of Moore. However, the Moore silencers were almost universally considered less effective. Still, they were being manufactured and saw some use. Supplies were short and the military was making use of what it could.

After WWI

Toward the latter end of the war, the US developed The Pedersen Device in secret. This was a special conversion kit for the 1903 rifle that allowed it to fire .30 caliber (7.62mm) pistol cartridges in a semi-automatic mode. The rifle needed a new ejection port cut out of the left side of the receiver and stock, while the actual device replaced the bolt of the rifle. The device was essentially the action (and very short barrel) of a pistol. A magazine holding 40 rounds stuck out of the 1903 at a 45-degree angle, and was easily replaceable. The device was designed to quickly change the M1903 to a short-range rapid-fire rifle, while allowing the rifle to be converted back with no detriment to its function (allegedly inside of 15 seconds). The Army produced around 65,000 of these devices, 6.5 million rounds of ammunition, and converted 101,775 rifles. The war ended before any were sent to Europe. Almost all of the Pedersen Devices were later declared surplus and destroyed in 1931.

Ammunition changed again in 1926. Learning from long-range German Mauser and machine gun fire in the war (and the 7.92x57mm cartridge), the Army switched to a 174 grain boat-tail bullet in the .30-06 cartridge. This became known as “Cartridge, Ball, caliber 30, M1”. M1 ammo became the standard for Army rifle competition teams and expert riflemen, offering greater accuracy over the M1906 variant. The M1 ammo trickled out to infantrymen and machine gun teams for general use.

By the late 1930s, changes in other armaments alleviated the need for long-range accurate machine gun fire in rifle calibers. In 1938, the army reverted to the .30-06 cartridge with a 152-grain flat-base bullet, similar to the original .30-06 ammunition. This ammo became known as “M2 Ball”.

Starting around 1930, the stocks on the new-production M1903 rifles were changed over to pistol-grip Type C stocks. These stocks improved marksmanship capabilities, and older 1903 rifles often also had their stocks changed after this point. The new rifles with Type C stocks were termed M1903A1 rifles, starting around serial number 1200051. The markings on the rifle were unchanged, so checking the serial number may be the only way to verify an original-production (not converted) 1903A1 rifle with Type C stock.

Through the 30s, the Army experimented with using the 1903 to train artillery teams. A small number of 1903A1 rifles were converted to the briefly-lived M1903A2 design. This was a stripped-down version of the 1903 intended to be used as an artillery training piece. Perhaps 1000 or so were converted, though they were later converted back to the standard rifle configuration. Remaining 1903A2 rifles are incredibly rare.

Returning briefly to the Winchester A5 scope; While the Army found the scope relatively unsuitable for field use, the Marines found the scope to be satisfactory for both their competitive teams, training grounds, and field use. In 1928 the telescope manufacturing rights were bought from Winchester by Lyman. Lyman began producing a marginally improved Lyman 5A scope, which the Marines eventually adopted in the years prior to WWII.

WWII

The M1903 saw new production through private manufacturers. Remington Arms and Smith-Corona Typewriter companies began production around 1941 and 1942, respectively.

Remington’s M1903 rifles start at serial number 3,000,000. They were made with mothballed tooling from Rock Island Arsenal, in storage since 1919. As such, the rifles were actually nearly identical to the 1919-made Rock Island rifles… at least at first. Remington began requesting changes to their production methods and parts to ease production, which the Army agreed to. Milled parts were replaced with stamped parts gradually. Milled parts from Remington are stamped with an “R”. Smith-Corona 1903 rifles were largely unmarked, though they began production with the slightly-later model “1903A3”. Over time, the original tooling from Rock Island wore out, and further production changes had to be made.

By serial number 3,300,000 at the Remington Factory, the model name would be changed from M1903A1 to M1903A3 to reflect the changes in production standards and design specifications. The new 1903A3 included a few changes from the earlier model: the rear sight was changed over to an aperture sight mounted at the rear of the receiver (to accommodate M1 Garand trainees), a stamped and rounded cartridge follower (which alleviated some of the jamming problems by sheer coincidence), and stamped furniture. The rear sight’s elevation spring weakened over time, which caused the sight to lose its setting. The cartridge follower’s switch from milled to stamped was intended to simplify production, but ended up also being functionally useful.

Production standards were even eased for the barrels - switching to a two-grooved rifling with lower-spec steel alloy. The action’s alloys had similarly relaxed specifications. As the war went on, further finishing and machining standards were dropped. The rifles with War Emergency barrels shipped with a printed note stating that the reduction in grooves did not affect accuracy. No mention was made of the alloy, though it seems to have held up.

Many of the M1903A3 rifles used in WWII do not have their original barrels. The primers used in the .30-06 ammo of the time were highly corrosive, and troops often did not have time or supplies to clean their weapons often enough to save the barrels. If the troops were stationed somewhere especially humid or wet, the situation did not improve.

On the sniper-rifle side of things, the U.S. Army didn’t officially have any. Any sniper rifles left from WWI had been disposed of. By 1942, when Allied forces invaded Guadalcanal and North Africa, the Allied forces were facing off against WWI Enfield and Pattern 1914 sniper rifles. The U.S. Army’s Ordnance Department figured it could save time and money designing a sniper rifle based on the new 1903A3 platform.

The pressure to produce enough arms and ammunition for the front lines was strong enough that the new 1903A4 was not marked differently - instead, the marking was spaced out to allow room for the optic’s mount to fit. It still read 1903A3. The rear peep sight had to be removed to fit new optics, and the front blade sight was never installed on the barrel. Lastly, the bolt handle was machined to be somewhat concave, keeping it from hitting the scope tube when flipped up. Aside from the changes to mounted optics and bolt shape, the 1903A4 rifles were merely 1903A3 rifles that were selected for having receivers and barrels that nearly perfectly fit design specifications.

M1903A4 rifles of original government production come in a few serial number blocks: 3407088-3427087, 4992001-4997045, Z4000000-Z4002920. From the A4’s formal designation in February of 1943 to the end of the production project in June of 1944, 28,365 rifles were produced. Any of the A4s found to be insufficient were to be converted back to the 1903A3 model.

The new Redfield scope mount removed the standard rear peep sight on the M1903A3, and fit a Weaver model 330 or 330C scope on top. The Redfield Jr. bases were marked “Redfield”, while the vertical-clamping rings were unmarked. The Weaver 330C sight was actually a commercial optic that had appeared on the market in 1930. When the military began using it, they designated it the M73B1 and marked it as such (excepting a few hundred early A4s with the commercial 330-C scope).

The Weaver scope was a fixed 2.75x scope with internal adjustments - essentially a straight tube of narrow diameter, with two adjustable knobs back near the eyepiece. It sat over the top-loading ejection port, which meant charging clips could not be used to load the rifle. The optic had a fairly wide field of view - around 35 yards when viewing targets 100 yards away. The glass fogged up quite often, and the adjustments could be unscrewed (if rotated counter clockwise) or broken (if forced clockwise) easily. It was not the military’s first choice in optics, though it was the one that had been available at the time.

Shortages and supply prioritization prevented the new 1903A4 from reaching the front lines until the end of 1943. As a further issue, the Ordnance Department’s first choice in optics - the Lyman Alaskan - was not ready in time, as Lyman was unable to meet delivery requirements on the project. The Lyman Alaskan was originally designated the M73, though changes in available alloys (and the initial adoption of the Weaver-design M73B1) eventually led to the Alaskan being termed the M81 (if it had a crosswire reticle) or M82 (when made with a tapered-post reticle) in military configurations.

Springfield M1903 rifles captured by the German forces were designated Gewehr 249(a).

Towards the end of the WWII, the Marine Corps rifle team began outfitting some 1903A1 rifles with an 8X Unertl scope. This adaptation of the A1 became known as the “USMC Model 1941 sniper rifle”. The Unertl scope differed heavily from the earlier M73B1 and M82 scopes of the Army, with triple the magnification, increased size and weight, externally-adjusting mounts, and recoil-reducing sliding of the scope tube. By keeping the same rifle and mounting system as the Winchester A5 scope, the Marines maintained mount interchangeability between their A5 and Unertl 8X scopes, and trained at home with their expected equipment in the field. The Marines’ 1903A1/Unertl combination was readily employed by sniper-observer-scout teams (scout snipers).

The Marines were still using the Winchester A5 and Lyman 5A scopes at the time of the Unertl’s adoption. The Marines also did not switch to the new rifle - the Model 70 - in order to keep the variety of rifles in the field somewhat simpler. This led to some confusion among ordnance depots and intelligence reports, which did not always know if they were talking about the 5A or the Unertl on the 1903A1.

One additional alteration to the Unertl scope is significant to the modern CMP (Civilian Marksmanship Program) competitor; The scope slides under recoil, reducing the potential for reticle breakage or loosening of the glass. The Unertl scope had room for a return-spring to be mounted on the scope tube, which would return the scope to battery without the rifleman needing to reach up and pull the tube back manually. However, the Marines felt that sand could easily get trapped in the spring, eventually scraping and scoring the sides of the scope tube. As such, the spring was abandoned. Ingenuity eventually found other ways to simulate the spring - one of the most common being a piece of truck tire inner tube stretched between the front clamping ring and rear mount.

After WWII

The 1903A3 and A4 continued on in use through the Korean and Vietnam wars alongside the USMC 1941, though their active service gradually declined. The Marines eventually declared the M1903A1/Unertl combination a limited standard, and recommended switching to the M1C. The last M1903 variants in military service exited around 1974.

In sum total, the 1903 saw combat through:

- The Mexican Revolution (1910-1920)

- World War I (1914-1918)

- The US Occupation of Haiti (1915-1934)

- The Chinese Civil War (1927-1950)

- The Second Sino-Japanese War (1931-1945)

- World War II (1939-1945)

- The Cuban Revolution (1953-1959)

- The Vietnam War (1955-1975)

Far More Recently

The last 588 remaining 1903A4 rifles in military inventory were destroyed during the Clinton Administration.

Leave a comment (all fields required)